AMA Plastics: Redundancy and Optimal Performance from HyperGrid and Microsoft Failover Clustering

AMA Plastics is a 165,000-square foot manufacturing facility, running 94 machines 24 hours a day, seven days a week. The manufacturing processes relies heavily on the software solutions that are hosted on the in-house servers. This software is used to manage a wide variety of functions used in managing company workflow and accounting.

With the increased demands of customers, and the addition of new clients, AMA Plastics needed a fast performing, optimized, stress-free solution. They were faced with end of life equipment that needed to be replaced and/or upgraded and did not want to put resources into accommodating large storage requirements or upgrading physical infrastructure.

Solution

Solace IT Solutions used HyperGrid virtualized servers to provide a strategy that not only addressed these performance issues, but also provided redundancy and zero-downtime recovery options. This solution was optimal for a small to mid-sized manufacturing company with high availability and compact design and scalability requirements.

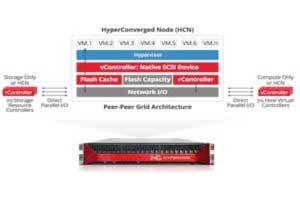

The HyperGrid solution is delivered via two all-flash HyperConverged Appliances running software that combines compute, network and storage into a two 2U systems that can be installed in as little as 5 minutes. HyperGrid appliances connect together to create a software-defined infrastructure fabric called HyperWeave. HyperWeave is plug-and-play, automatically creating web-scale infrastructure without requiring specialized skills and experience.

Furthermore, HyperGrid’s solution provided accommodations for legacy applications through the addition of virtual machines. Using compartmentalization (or sandboxing) old applications that could not be upgraded or easily updated with unique system requirements were secured and segmented from other servers and shares at the machine level and the memory managed through the Hyper-V interface. This not only provided greater levels of stability at reduced licensing costs, but kept these applications running longer with a smaller overall memory foot print.

Benefits

AMA Plastics has shown both time and money savings with this solution in a very short period of time. Inventory reports have been reduced in time from 50 minutes to 3 minutes, while the hyper-converged virtual environment has allowed the company to scale technology and bring on new business without the need of additional hardware. The ERP software is functioning at optimal performance, promoting production and performance; while legacy applications essential to company operations are isolated and kept stable through the use of a customized virtual environment.

Overall, this solution provided a redundant, optimal uptime environment that increased overall performance, improved manageability, and allowed for future growth.

Client: AMA Plastics

Focus: Failover Clustering, Hyperconverged, Hypergrid, Virtualization

Date: July 2017

Challenges

Lack of mobility

Aging equipment

Slow speeds

Inconsistent connectivity

Solution Highlights

Azure Based Virtual Machines

SSD hosted application storage

Remote Desktop to Azure

Session Hosts

Azure AD connect

Windows 10 Professional

Result Highlights

Mobility

Speed

Security

Cloud Solutions Utilized

Office 365 E3

Azure

Azure AD

Dynamics CRM